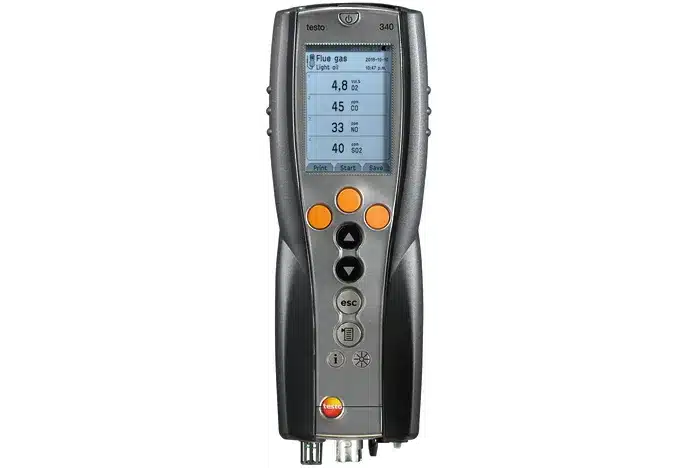

Compact design combined with reliable engineering makes testo 340 the ideal analyser for commissioning, service and maintenance work as well as measurements for monitoring purposes; Industrial burners, Stationary industrial engines, Gas turbines & Thermal processes.

- measurement range extension for Single dilution slot or optional for all sensors

- pressure-/ flow-measurement standard in every testo 340

- automatic flow-controlled gas pump

- 18 standard fuels and additional 10 user-defined fuels – Fuel data is calculated using software easyEmission

testo 340 is the ideal, versatile hand-held analyser for industrial flue gas analysis and emissions the 340 offers benefits such as: The unique measuring range extension feature facilitates unlimited measurements even at high gas concentrations. The testo 340 is equipped with an O2 sensor as standard. 3 additional gas sensors can be individually configured at any time so your analyser is optimally adapted to your measurement job.

Analysis of the gas atmosphere (thermal processes)

Flue gas analysis is used for thermal manufacturing processes, from ongoing emission control, via setting and optimisation of combustion systems, through to process monitoring. Flue gas analysis instruments serve to optimise operations and save fuel. At the same time, flue gas measurement enables checking and monitoring of flue gas emission limit values laid down by the authorities, along with functional testing of permanently installed emission instruments. Flue gas analysis instruments are increasingly used for monitoring process and product quality.

Advantages of the testo 340

Ideal for measurements at high concentrations

- When recording extremely high concentrations, the measuring range extension is automatically activated. This enables continuation of the measurement. The gas sensor is not subjected to any higher stress than it is at low gas concentrations. This ensures the sensor has the longest possible service life.

Service measurement on industrial engines

Flue gas analysis instruments are one of the items of equipment that are used on a daily basis by service engineers to achieve optimum tuning of engines. Flue gas measurement is used on industrial engines when they are commissioned, at regular maintenance intervals or for troubleshooting when they are running in an unstable way. The background to flue gas measurement is tuning the engine to the optimum operating parameters while complying with the limit value regulations in force. Maintenance work that is carried out regularly makes an important contribution to avoiding downtimes over the long term, to ensuring the quality of the system and thus a high level of efficiency and to having a significant influence on emission levels.

Separate NO and NO2 measurement

- The real NOx value is measured with the NO and NO2 sensor combination. In gas engines, the NO2 component of the NOx value can fluctuate greatly, so the separate measurement of each of the gases is necessary for correct NOx values.

Measurements even at high CO concentrations

- At unexpectedly high concentrations (up to 50,000 ppm), the automatic dilution of the sensor with fresh air allows measurements even when the engine conditions are not defined, without negatively affecting the service life of the sensor.

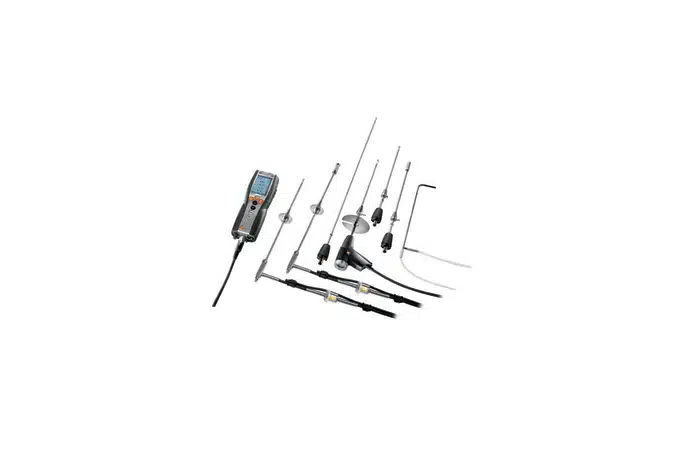

Special flue gas probes for industrial engines as an accessory

- These probes are highly heat-resistant and specially designed to compensate for different pressure conditions, e. g. for measurements before and after the catalytic converter.

Engine-specific parameters

- The most important parameters for industrial engines such as O2, CO, NO, NO2, NOx and Lambda can be displayed simultaneously.

Service measurement on industrial burners

The testo 340 flue gas analysis instrument offers service engineers a vast range of technical functions. In addition to compliance with environmental regulations, it can also be used to check correct functioning and to optimise burner efficiency. Flue gas measurement is used on industrial burners for safe and efficient commissioning, at regular maintenance intervals or for troubleshooting when they are running in an unstable way.

Time saving through helpful instrument pre-settings

- Typical fuels, a sensible sequence of flue gas parameters in the display and useful instrument settings are preset for each application. Tips on the display take the user through the measurement (no prior knowledge specific to the instrument needed). The testo 340 is ready for operation within just a few minutes.

Unrestricted measuring at high concentrations

- When commissioning burners or carrying out measurements on unfamiliar systems, very high concentrations can occur unexpectedly. The measuring range extension is automatically activated in such cases.

Always ready for use – even in tough day-to-day work

- The robust housing protects the measuring instrument from knocks.

testo 340 flue gas analyzer, protocol certificate, shoulder strap, O2 sensor and integrated flow and pressure difference measurements.

PLEASE NOTE: Your testo 340 must be fitted with a second gas sensor for it to work. Up to three additional sensors can be fitted.